Category Archives: Lean

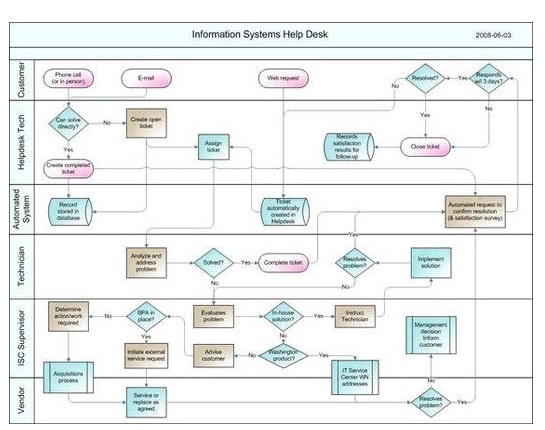

Process map with swim lanes

SIPOC lean six sigma

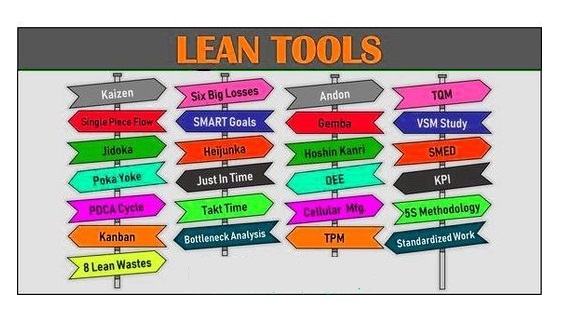

Top lean tools

Lean Six Sigma 8 Types of Waste Explained

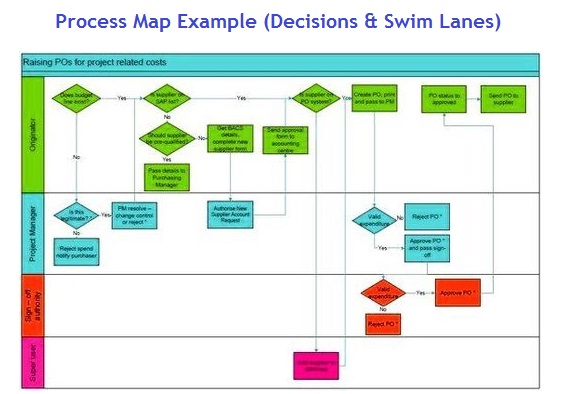

Process map with decisions and swim lanes

DMAIC phases explained

The DMAIC process follows 5 phases, which are foundational for the process improvement efforts, setting goals, and analyzing results. The five phases are: 1. Define, Measure, Analyze, Improve and Control. What Does DMAIC Stand For? It represents the 5 phases View diagram DMAIC phases explained

Lean Six Sigma 8 Types of Waste Explained

Sample SIPOC

SIPOC is a high level representation of a process and its participants. Below diagram is an example of a SIPOC SIPOC stands for Suppliers – Inputs – Process – Outputs – Customer. It shows the key relationship of one phase View diagram Sample SIPOC