Category Archives: Lean

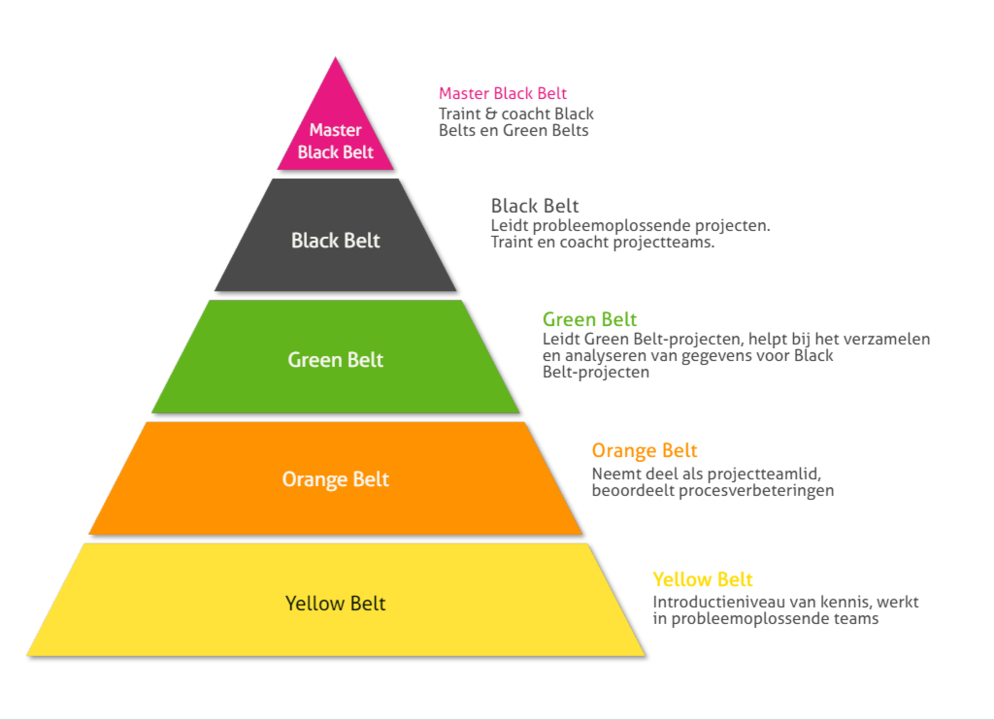

Lean six sigma belts pyramid

TPM Total Productive Maintenance

Total Productive Maintenance is a lean six sigma framework that stands on 5 pillars that are elimination of main problems, autonomous maintenance, planned maintenance, early management of new equipment, education & training on the job. TPM framework below also lists View more TPM Total Productive Maintenance

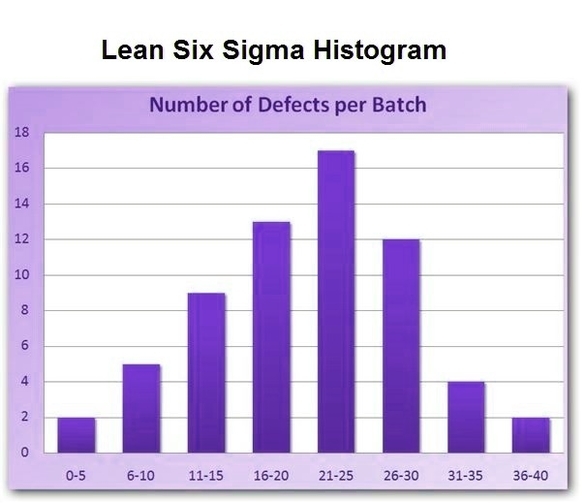

LSS Histogram

Push vs pull system

Push vs pull system diagram below explains the difference between two key lean six sigma process types. Push system is when material is pushed into downstream workstations regardless of whether resources are available. Pull system – materials are pulled to View more Push vs pull system

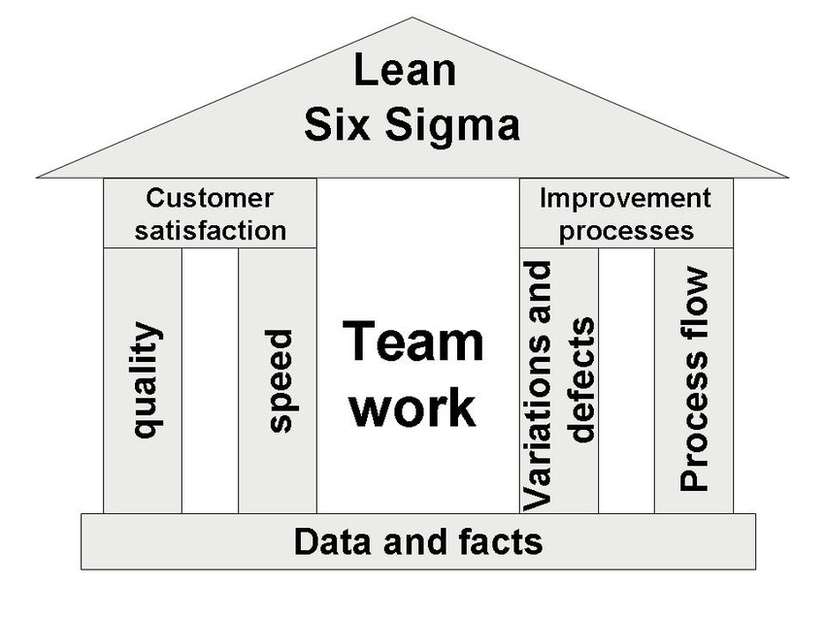

Lean Six Sigma Design Principles

Lean six sigma design principles include quality, speed to increase customer satisfaction, decreasing variations and defects, improving process flow while heavily relying on data and facts and doing it all through effective team work. The LSS design principles diagram below View more Lean Six Sigma Design Principles

PDCA cycle

PDCA cycle stands for Plan, Do, Check, and Act. Plan for change to bring about improvement, Do change on a small scale first to try them, check to see if changes are working and investigate selected processes, act to get View more PDCA cycle

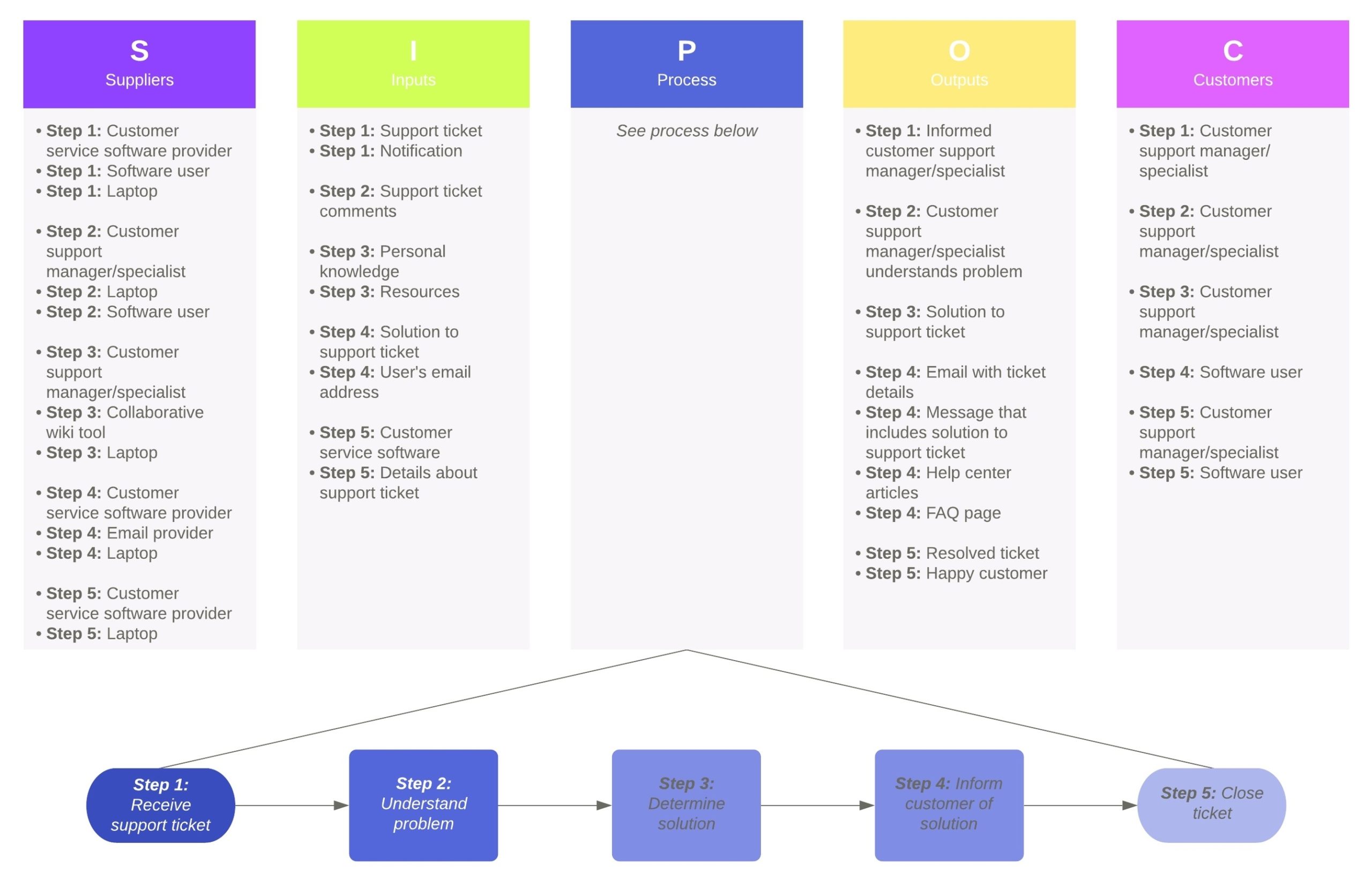

Sipoc flow example

Sipoc is a lean six sigma tool that helps map the process at a high level while stating who the suppliers are, what are the inputs, what is the process, what are outputs and customers. SIPOC is a great tool View more Sipoc flow example

DMAIC tools for each phase

DMAIC Phase Tools Used: Define – Define project goals and customer deliverables, develop Problem Statement, Goals and Benefits; Identify Process Owner and Team Members; Define Resources; Develop Project Plan and Key Milestones By using Lean Six Sigma DMAIC approach, companies View more DMAIC tools for each phase