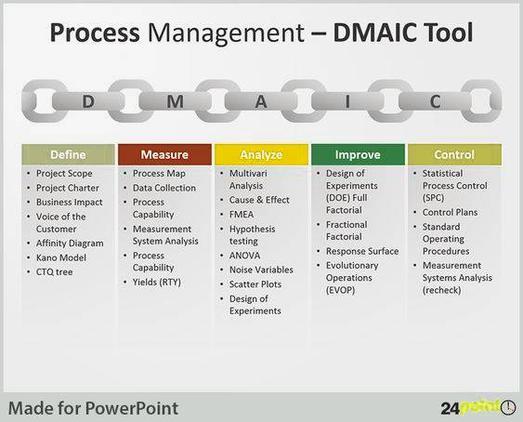

The DMAIC improvement cycle is the core tool used to drive Six Sigma projects. However, DMAIC is not exclusive to Six Sigma and can be used as the framework for other improvement applications. DMAIC is an abbreviation of the five improvement steps it comprises: Define, Measure, Analyze, Improve and Control.

The DMAIC methodology has its roots in the PDSA (“plan, do, study, act”) cycle developed by statistician Walter A. Shewhart at Bell Laboratories in the 1930s. But the technique as we know it today has been shaped by some of the largest organizations in the world such as Toyota, Motorola, GE, and Ford Motor Company.

Here are 4 key guidelines: Make sure there is potential to reduce lead time or defects while resulting in cost savings or improved productivity Once you’ve selected a good project, you and your improvement team can apply DMAIC to dig into process issues and deliver quantifiable, sustainable results. Now, on to the DMAIC process!